[su_list icon=”icon: angle-double-right” icon_color=”#3498db”]

- Part 1 – Tyre as a vertical spring

- Part 2 – Road Interaction & Contact Patch Grip

- Part 3 – Longitudinal Forces

- Part 4 – Lateral Forces

[/su_list]

A very important aspect for both longitudinal and lateral forces is how tyre’s maximum achievable force changes with respect to the vertical load or, in other terms, how much the lateral/longitudinal friction coefficient varies with respect to Fz.

In general, the maximum planar force that the tyre can produce grows as the Fz increases its magnitude. This happens at a smaller and smaller rate as the vertical load gets bigger and bigger.

The trend with which the friction coefficient varies with respect to the vertical load Fz is often referred as Load Sensitivity. This is an extremely important parameter (as we will see more in details talking about downforce and handling), because it defines a kind of efficiency for the tyre and how it reacts to changes in vertical load. In other terms, the load sensitivity tells us how much we could get back from the tyre in terms of grip for each additional Newton / kilogram of vertical force that we apply on it.

It is normally a good approximation to describe the relationship between friction coefficient and vertical load as linear. This means that, if we plot how µ evolves with Fz, we will draw a straight line. Our line will point down as we move to higher vertical loads, because µ gets smaller if Fz gets bigger:

Assuming that a linear relationship between friction coefficient and load is really a good approximation, we could use the following equation to define it:

µ = a + b * Fz

where a is friction coefficient’s value at a vertical load equal to zero (or the line intersection with vertical axis) and b (negative) is the load sensitivity.

As the planar force (longitudinal or lateral) also depends linearly on the vertical load:

F(x,y) = µ(x,y ) * Fz

It follows that the planar forces depends on the square of the vertical load:

F(x,y) = (a + b * Fz) * Fz

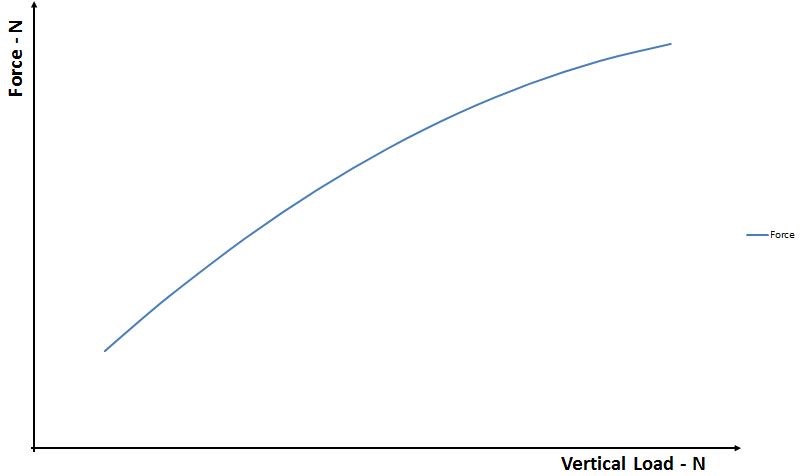

From a graphical perspective, the relationship between planar force vertical and load can be represented with a quadratic curve, like the following one:

What this plot tells us is that, if the vertical load increases, the rate that the planar force grows decreases. We could even reach a point where a further increase of the vertical load could actually lead to a decrease of tyre cornering/braking/accelerating potential. However, tyres are normally designed with a specific application in mind and are built to handle effectively the load they encounter running on the track, so this phenomenon is not common.

As we said already, the main consequence of load sensitivity is that we get smaller and smaller planer forces for each increase of our vertical load. This parameter depends on tyre design and structure, including also the materials in use.

Normally, lateral force load sensitivity is bigger than the longitudinal one. This means that the cornering friction coefficient degrades quicker than the longitudinal, as the vertical load increase.

A concept that we need to stress again and again is that the load sensitivity, because of the way we defined the friction coefficient (the maximum lateral/longitudinal force that the tyre can produce at a certain vertical load, which means we will have to pick curve’s peak value for our ratio), gives us the maximum potential of the tyre. This is reached only for a certain slip ratio longitudinally and for a certain slip angle vertically. At different slip ratios / slip angles, the tyre will only explore a portion of this potential.

As we will analyze more in details, the load sensitivity is one of most important tyres feature, because it defines how much a certain setup change could influence how the car handle.

Just to get a feeling about this, we can imagine a car negotiating a corner at a certain speed V. Because of lateral acceleration, the car will experience the action of an inertial force, that we identified in our cornering forces analysis with the following equation:

Fy= -m * Ay

and will be equal in magnitude to the sum of the four cornering forces coming from each tyre.

Since this force acts on the car center of gravity (CG) and this point seats above the ground, we will have a moment (given by Fy multiplied by the distance between CG and ground), that means an action that tries to roll the car toward the outside of the corner. This will produce unbalance on the wheel vertical loads, with a portion of inside tyres loads moved to the outside tyres. We call this phenomenon load transfer.

Load Transfer

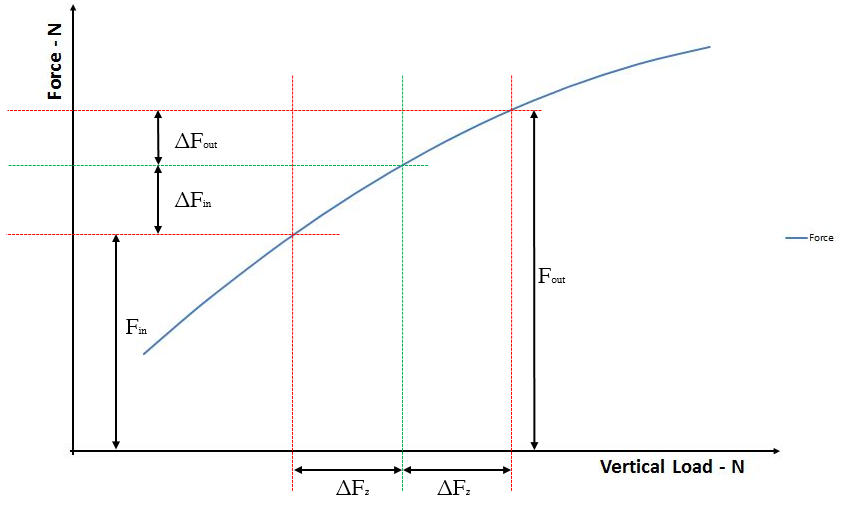

As the above picture shows, because of the weight transfer, both the cornering and vertical force acting on the outer tyre will be bigger than the inner ones.

As we mentioned before, as a tyre vertical load increase, the cornering force grows always less for a certain finite change of Fz.

In a cornering situation, even assuming that the sum of the vertical forces acting on the two tyres of one axle have the same value as with the car travelling on a straight line (and, hence, with no load transfer), the cornering force gain that we obtain on the outside wheel because of a bigger vertical load is smaller than the lost that we have on the inner wheel, because of a smaller load.

This can be seen at best in the following picture. Here we clearly identify as, for a certain ΔFz (difference between a wheel’s static load and the load we have with weight transfer in place), we get a ΔFout smaller than ΔFin (with F being the cornering force produced by each tyre). This means that the increase in cornering force that we get on the outside tyre is smaller than the lost that we have on the inside one.

We conclude that because of tyre load sensitivity, every load transfer produces a degradation of car’s cornering potential.

This is also the reason why a low center of gravity is so crucial for a race car, as the lower is the CG, the smaller will be the load transfer.

Ideally, if we could have a tyre with lower load sensitivity, the effects of the center of gravity height would be smaller.

Part 6 next week – combined tyre forces.