[su_list icon=”icon: angle-double-right” icon_color=”#3498db”]

[/su_list]

We mentioned in the previous article that some of a tyre’s features can be linked to what happens when it rolls on a surface.

The analysis of a rolling wheel, in particular the contact patch, is a very useful starting point to start talking about how a pneumatic tyre interacts with the road.

Let’s consider a tyre that is free rolling on a surface. If we concentrate our attention on the contact patch center at a certain point in time and follow the movement of this point in the following instants, we will see that whilst said point is in contact with the road, there is no relative movement between it and the road itself.

It may sound absurd, but the tyre contact patch of a vehicle traveling at constant speed doesn’t move with respect to the road surface. Each point of the wheel describes a “cycloid” during wheel’s motion.

As the picture shows, the center of tyre contact patch doesn’t move with respect to ground, although it does experience an acceleration. The image above shows actually what happens with a rigid wheel rolling in place. A rigid wheel has a cylindrical shape and touch the ground on a line.

The situation doesn’t change if we consider a car tyre, where the contact patch has a finite area that depends on tyre deformation and on the acting forces. Differing from the rigid wheel, a real tyre will experience the whole contact patch not moving with respect to the ground and then leaving it as the wheel goes on rolling, while another tread portion replaces it. The flattening of the contact area produces micro-movements between road and tread elements, but no global motion.

It is only when the vehicle brakes or accelerates that the contact patch and the road surface start to move with respect to each other. This is called relative motion slip. It is interesting to underline that a tyre (or its contact patch) that experiences slip(page) does not skid with respect to the road. Actually, as we will see, the forces involved with tyres slip are what makes possible for the tyre to avoid any skid.

Surface roughness

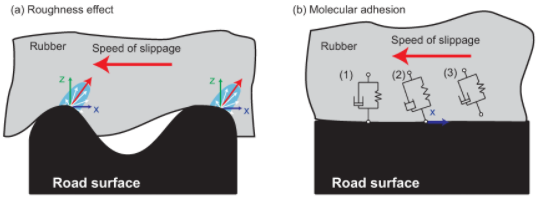

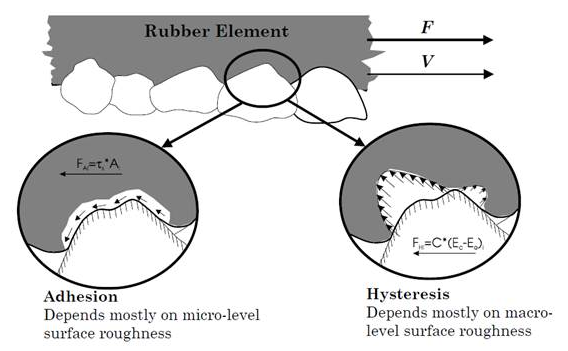

Two main phenomena are involved anytime there is a slip between tyre and road. The first one is often called indentation and it is mainly related to road roughness (road’s rough spot with sizes varying from 1 cm to 1 micron). As the name suggests, indentation is what happens when the road asperity penetrates the tread rubber during a slip phase. Because of its own flexibility, the rubber adapts to the shape of rough points on road’s surface and, because of its hysteresis, it doesn’t come back immediately to its original shape after the rough spot has been left.

The second mechanism is adhesion; it comes into play at a much smaller scale than indentation (hundreths of microns) and is amplified by tyre slip. It is the result of molecular interactions between rubber and road, which happen when the two are in contact with each other. Bonds are continuously formed and broken as a tyre moves on the road. This constantly stretches and breaks rubber molecules, generating friction between them and significantly increasing the bonding energy, which also depends on temperature and slip speed.

When analyzing road characteristics and how they affect tyres grip, experts normally refer to macroroughness and microroughness.

Macroroughness is the term identifying road irregularities when the distance between two consecutive rough spots is between 100 micron and 10 millimeters. It is linked to the dimensions of the aggregates used for road surface and contributes to indentation.

Microroughness refers to rough spot having a distance from each other between 1 and 100 microns.

Experts also refer to load bearing surface as the area of the surface where the rubber is physically in contact with the road, given a certain load and road characteristics. It depends not only on rubber features but also on the load pressing the tyre against the road.

There is a connection between load bearing surface dimensions and local pressure that each small piece of rubber experiences when in contact with the road. With very rough road surfaces, the load bearing surface is smaller and local pressure is bigger.

As the previous picture suggests, a vertical load press the rubber against the road surface and, because of its own flexibility, it “flows” into the roughness of the road and fills the space between a crest and the next one. This process is less and less effective as the load increase because there is, little by little, less and less space to be filled. As we will see, this is reflected in one of the most important features of a tyre in terms of handling, namely load sensitivity.

Grip Forces at the Contact Patch

Now that we dealt with the basics about how a tyre works and what is happening in the rubber-to-ground interface, we can try to understand how a tyre generates the forces that allow the car to drive through a corner, accelerate or brake.

Grip is actually a pretty generic word, used to identify many different things. It is probably more correct to talk about planar forces. This refers to the forces acting at the contact patch on the plane of road surface.

We need to keep in mind that a tyre will exchange forces with the road when traveling at constant speed, as there are always some resistances (like the rolling resistance, as we saw) that need to be overcome in order to maintain a certain forward velocity.

The situations where the tyre exchanges forces at a higher magnitude with the road are generally associated with high load maneuvers such as cornering, braking before a corner or accelerating out of it. As we will see, the tyre will often exchange combined forces with the road, which means a combination of longitudinal and lateral actions.

Whatever the direction or the magnitude of tyre forces, everything happens at the contact patch, where we have some rubber in contact with road surface; this is why it is important to understand exactly which kind of interactions take place.

As we saw, we can assume the tyre contact patch having no relative motion with respect to the ground during pure rolling. Indeed, we can describe what happens at the contact patch more like the interaction between a rubber pad being pressed against the road with a certain vertical load.

So with that in mind, let’s start describing how tyre forces are generated by considering a how a simple piece of rubber lying on a surface interacts with it. We will imagine applying a vertical Force Fz on the rubber by means of a metal plate lying on top. The rubber will deform vertically, becoming shorter and wider.

If we now apply a horizontal force F to the upper metal plate (which cannot move with respect to the rubber), the rubber will deform, initially without moving with respect to the ground. This situation is called shear. Although the rubber doesn’t move globally with respect to ground, there are already some micro-movements at the interface with it. This is the reason why such a situation is sometimes also called pseudo-slippage.

The micro-movements happening at the interface with the ground are also what determines the creation of a force Fx, that counteract F and allow the rubber block to remain in equilibrium and not to move with respect to the ground.

If we further increase the magnitude of our force F, we will soon reach a point where the whole rubber pad will start to move with respect to the ground, with a skid movement. There is in fact a value of F at which the rubber will start to slide, with Fx maintaining a constant magnitude.

The maximum magnitude of F where we still have no sliding is called Coulomb’s Friction Force and depends on the vertical Force Fz through the friction coefficient µ.

Fx = µ * Fz

Although this is not exactly what happens in real applications (as we will see, we cannot talk about Coulomb friction for a tyre), this simple case helps to understand what happens at the contact patch and how a tyre react to external forces. This serves as a base to understand how a tyre really works.

Part 3 next week will cover Longitudinal Forces.